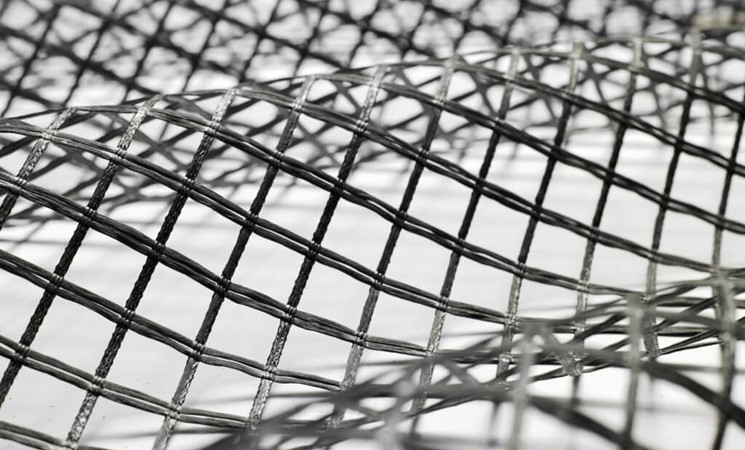

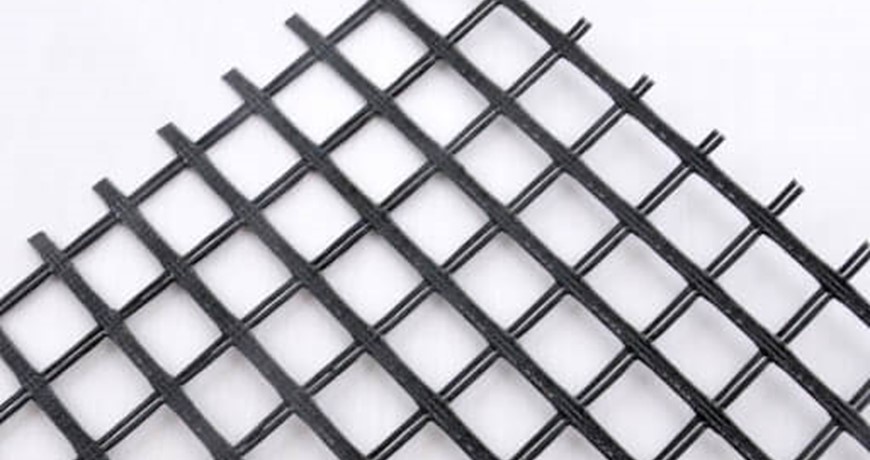

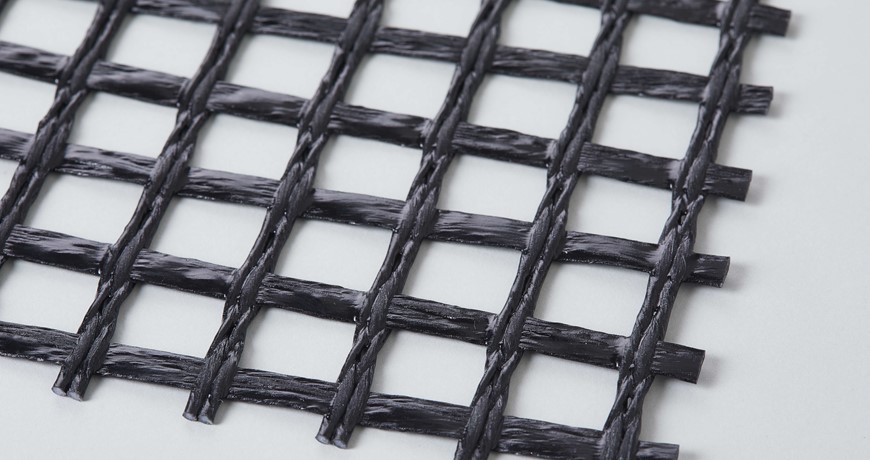

Soil Reinforcement

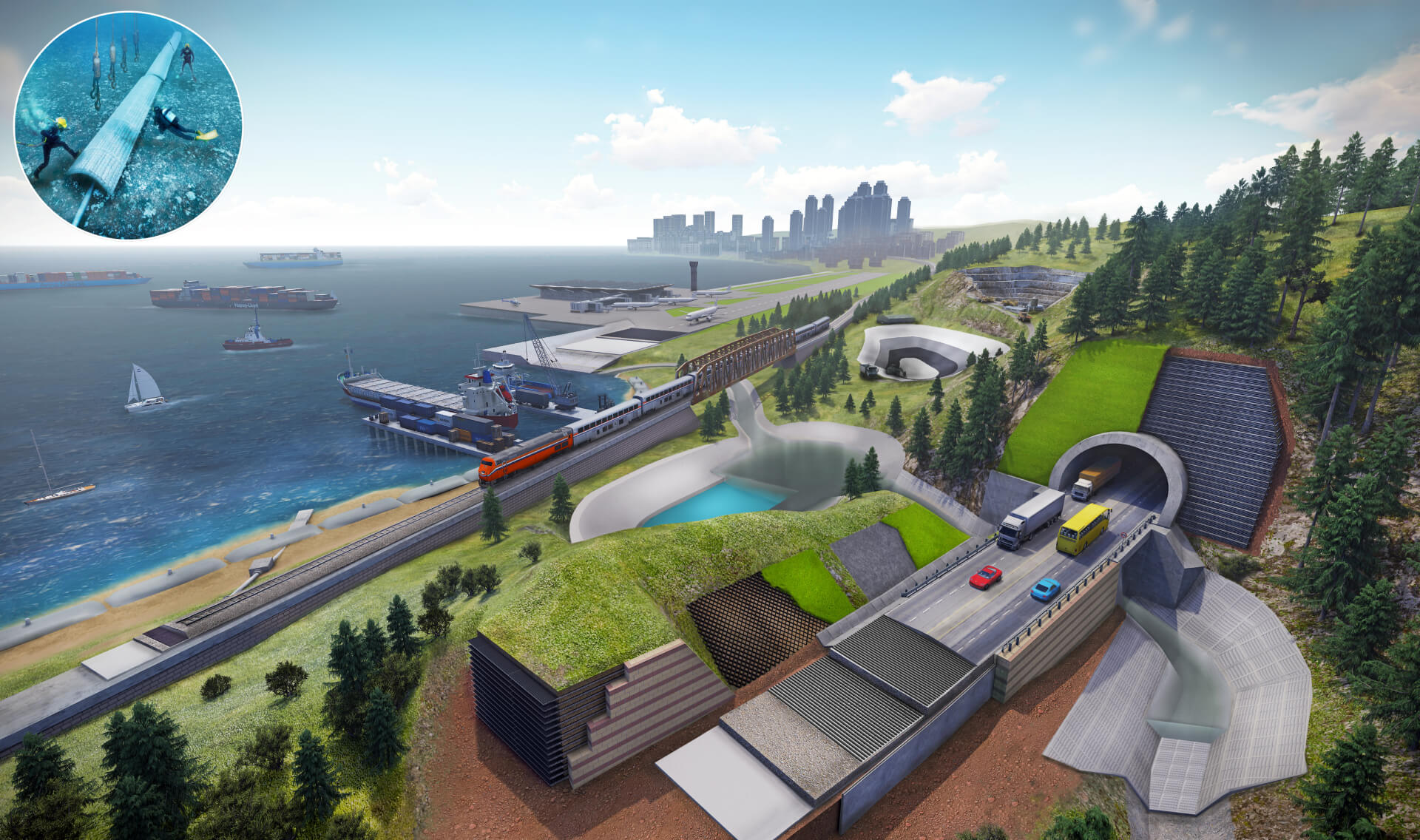

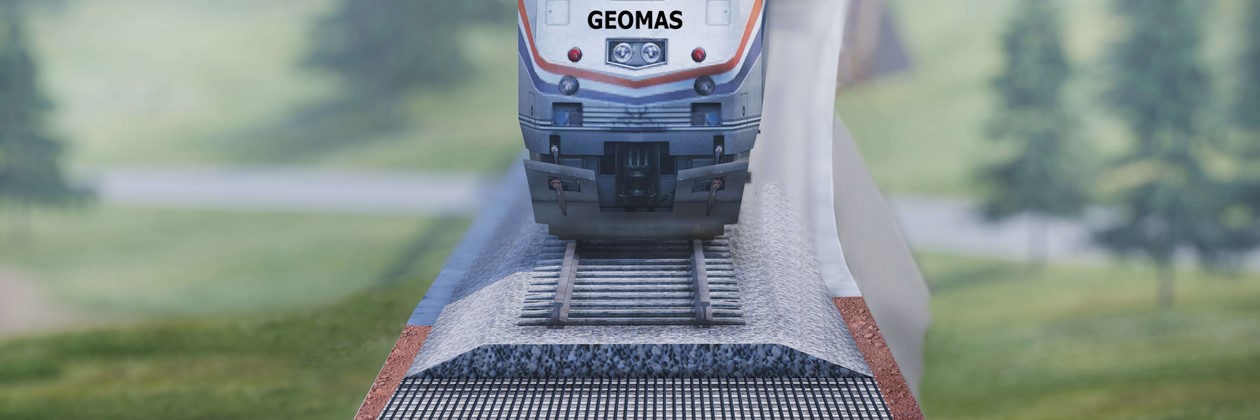

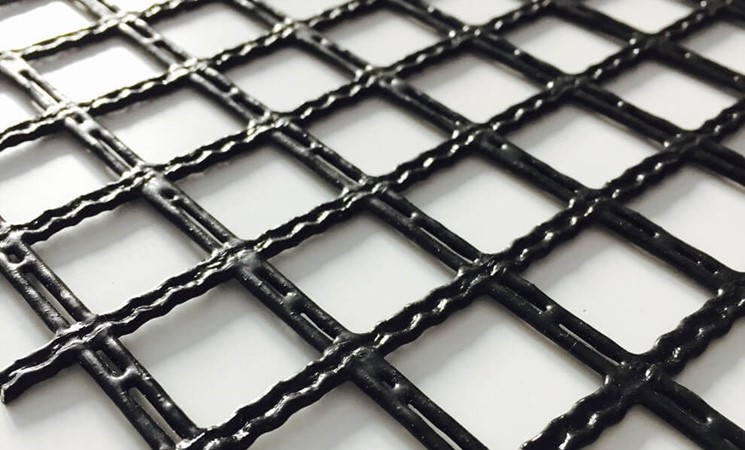

The engineering structure constructed are exposed to the stresses more than the soil safety stress, encountered with the problem for soil bearing capacity. These usually result in a permanent damage involving cracking, collapsing and breakage on the structure. Geosynthetic (geogrid, geotextile, geo cell, composit material) have been preferred reinforcement for soil structures to be prevented the ground safety stresses from exceeded by making the ground feel the stresses that will be transferred to the ground less. The engineering structure constructed are exposed to the stresses more than the soil safety stress, encountered with the problem for soil bearing capacity. These usually result in a permanent damage involving cracking, collapsing and breakage on the structure. Geosynthetic (geogrid, geotextile, geo cell, composit material) have been preferred reinforcement for soil structures to be prevented the ground safety stresses from exceeded by making the ground feel the stresses that will be transferred to the ground less. The geosynthetic reinforcement is improving the stability an embankments so it works like a mat foundation.

View