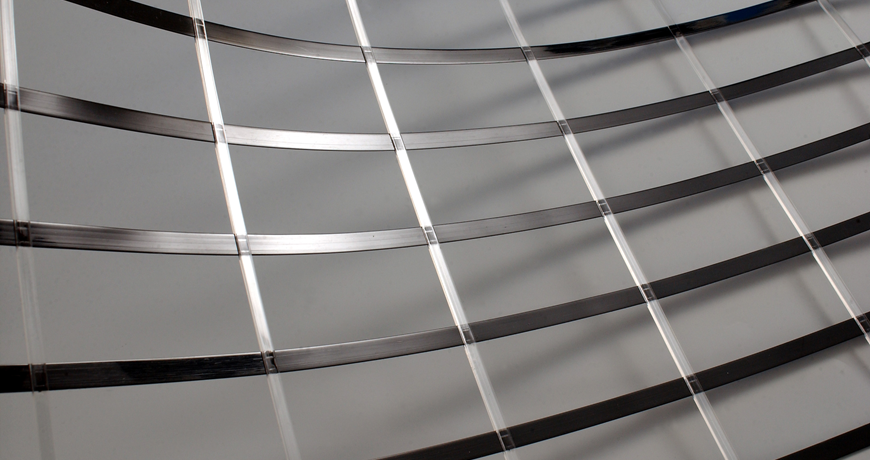

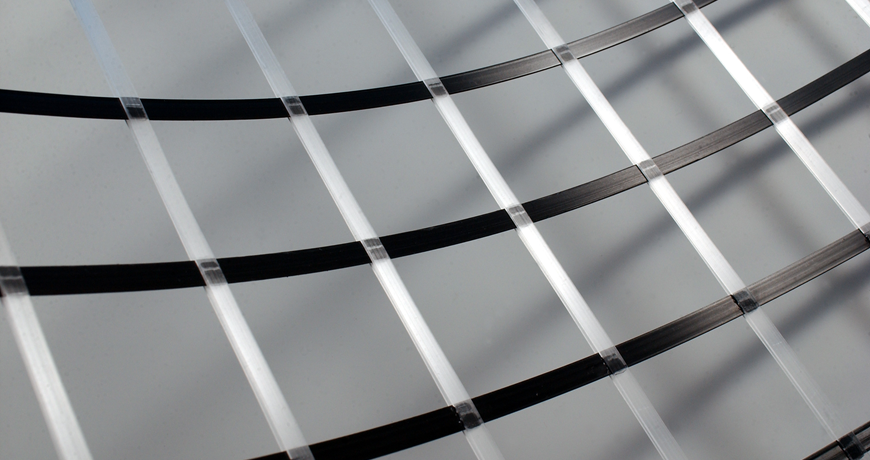

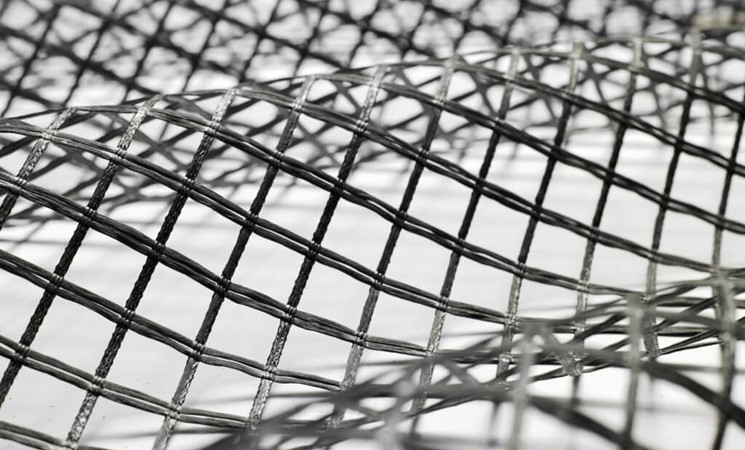

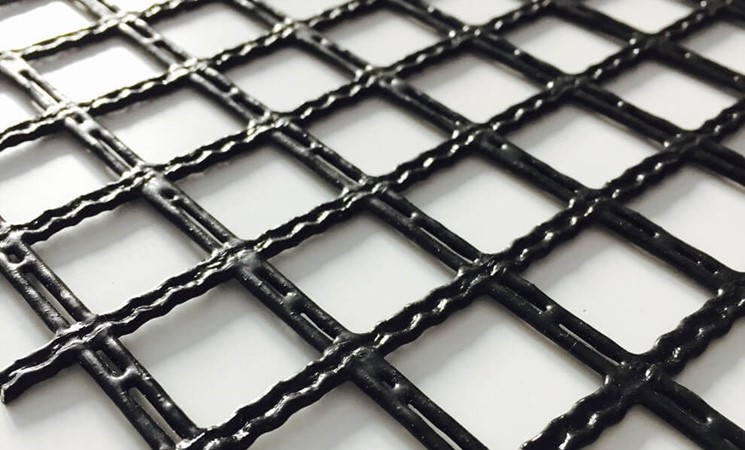

High stiffness and low creep properties

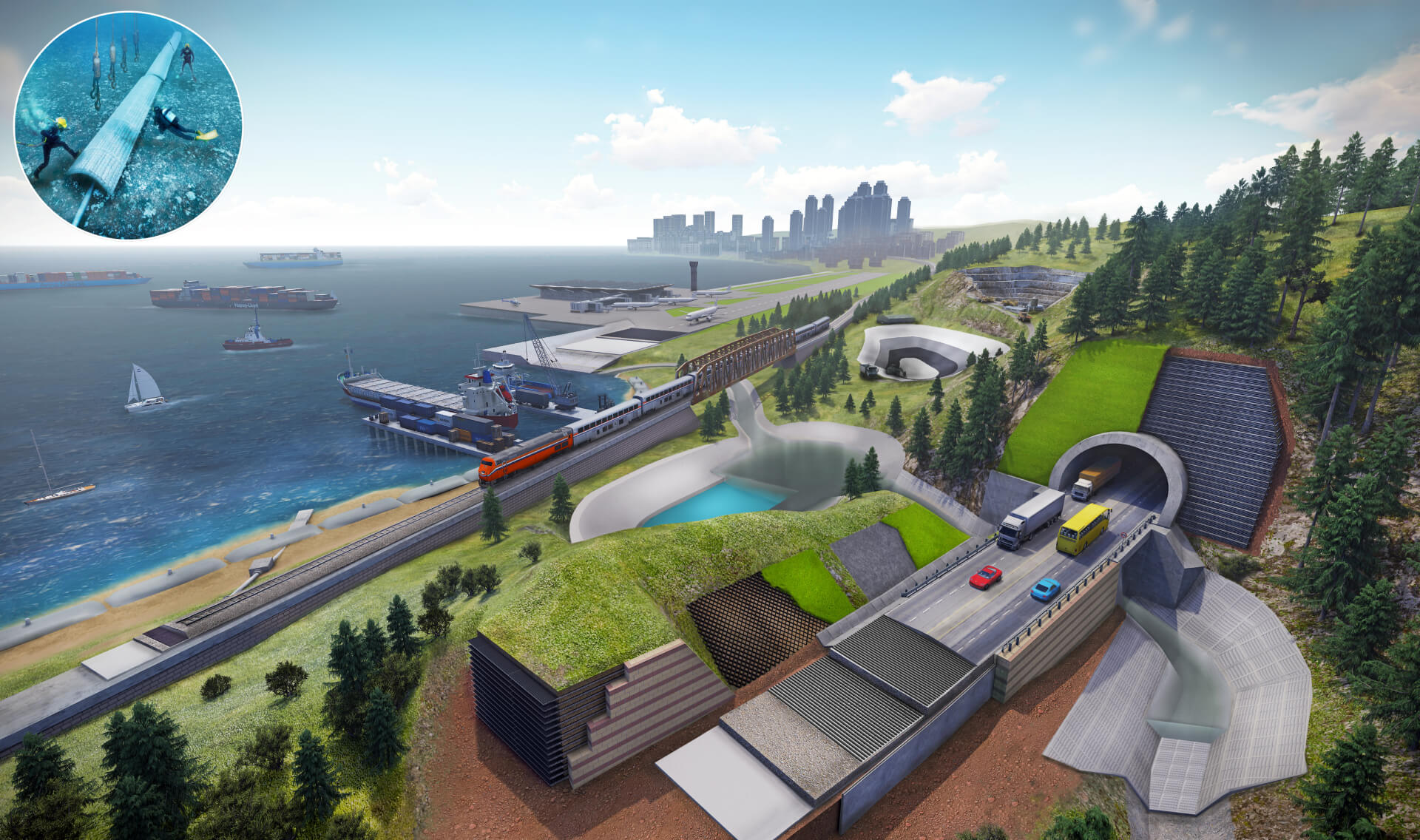

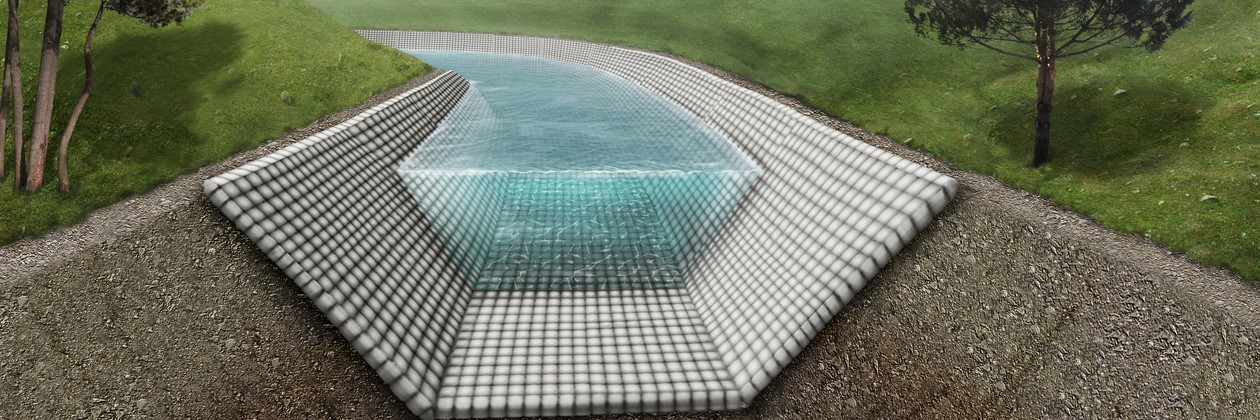

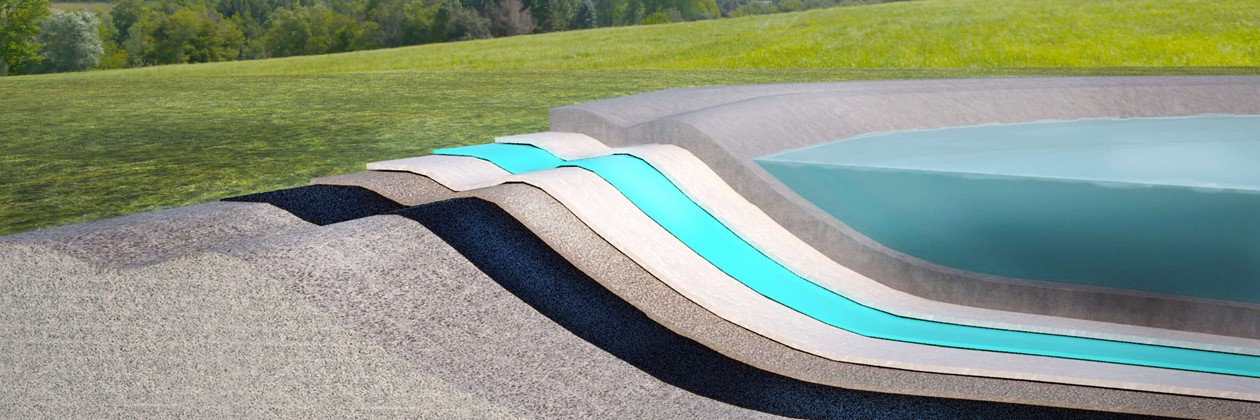

EnkaGrid MAX is commonly used to reinforce retaining walls, as well as subbases or subsoils with optimum interaction with all granular soil types. EnkaGrid Max is a high stiffness and low creep properties maximize soil performance, limits differential settlements during consolidation, increases the bearing capacity, increase the service life EnkaGrid Max is a high performance and cost effective biaxial geogrid composite used worldwide in civil engineering projects for reinforcing granular base courses and separating different soil layers. It is designed for achieving maximum bearing capacity and shear resistance.