Biaxial knitting polypropylene geotextile

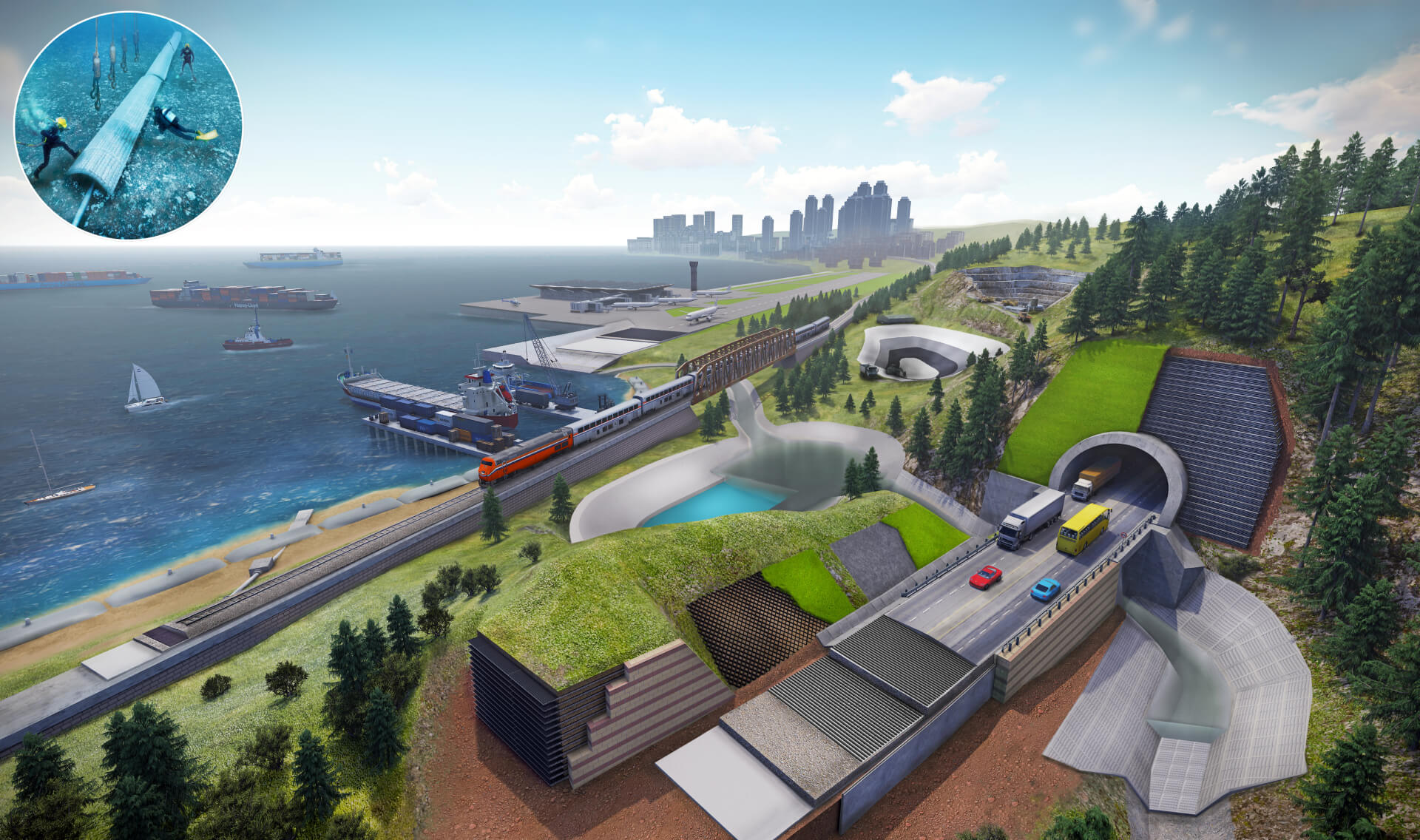

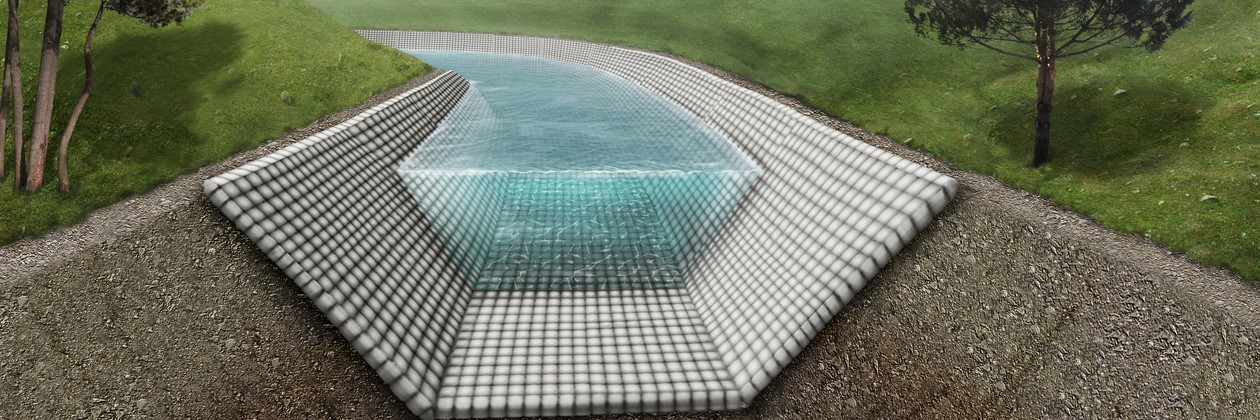

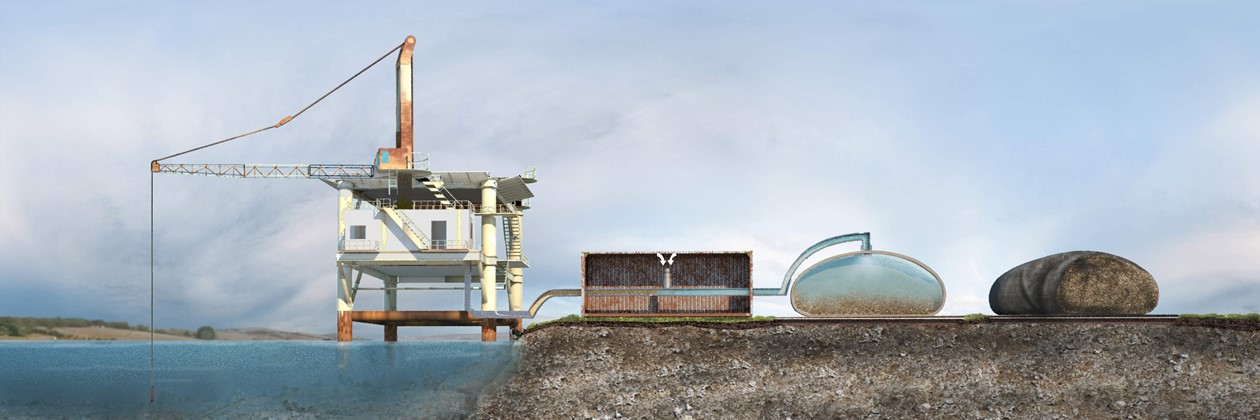

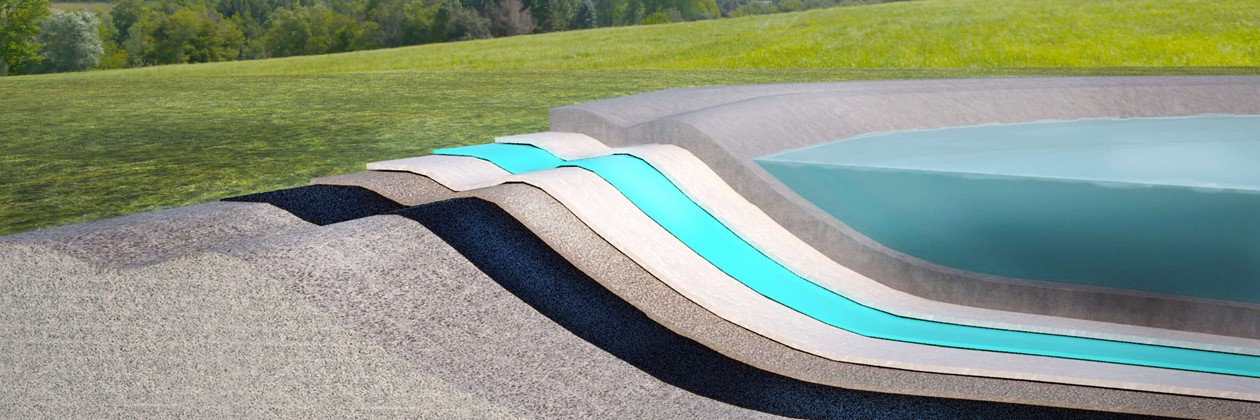

Geotex is specifically designed as a biaxial geotextile to provide excellent performance in various applications, including covering areas with a tensile strength of 100 kN/m, reinforcing soil in embankments and retaining wall systems. Its biaxial structure allows it to effectively distribute tensile forces in both directions, enhancing soil stability and preventing potential failures. Furthermore, Geotex is widely used for reinforcing granular base courses in road construction, enhancing their load-bearing capacity and longevity. Additionally, it serves as a reliable separator between different soil layers, preventing mixing and maintaining the integrity of the overall structure. With its versatility and high tensile strength, Geotex proves to be an essential geotextile material for numerous civil engineering projects, contributing to their durability, safety, and cost-effectiveness.